Welcome to,

Autocatsilver AB

State of the Art

Electroless and Autocatalytic Silver Processes

Space, Telecom and Electronics

New opportunities with Electroless Silver!

Electroless silver is also known as autocatalytic silver.

Our autocatalytic silver processes can be applied to different materials. Pure and dense silver layers will be achieved on:

Nickel

Copper

Silver

Gold

Technology

Autocatalytic silver is an alternative to conventional

electroplating and immersion processes. The

technology enables silver plating on high complex

geometries with narrow tolerances, resulting in high

quality performance. Hence, autocatalytic silver has

the potential to both improve performance and reduce

plating costs.

The autocatalytic nature of the processes means that

plating is continued as long as the substrate is in the

plating bath, without applying a current. This differs

from immersion processes, that only plates to a few

tenths of a micron and from electroplating, that needs

electrodes and an applied current, for plating.

Application

There are many potential applications within space, telecom and electronics:

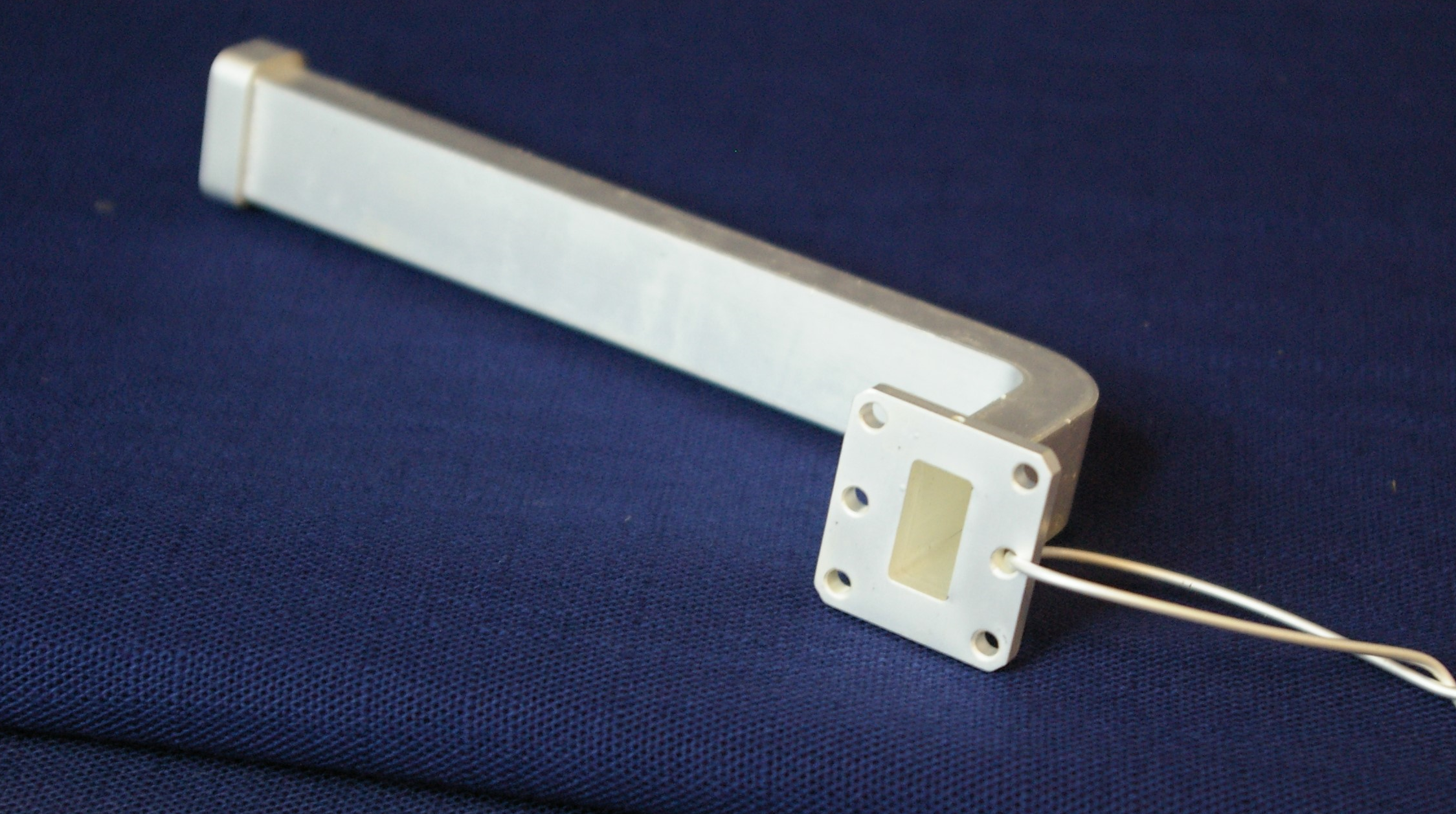

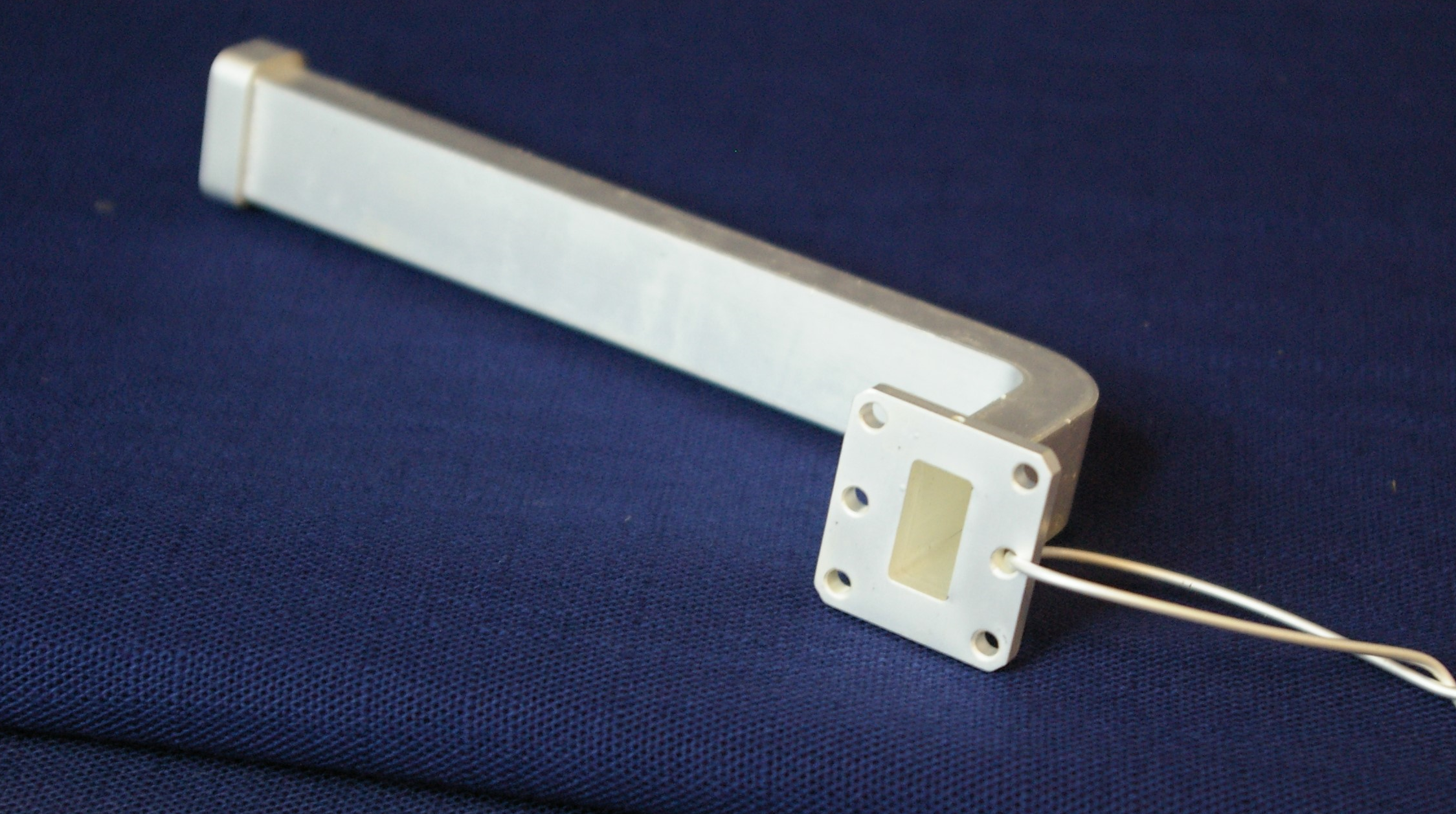

Autocatalytic silver plating, following electroless nickel plating, for microwave or mm-wave components of machined 3D-printed aluminium.

Autocatalytic silver plating, following an electrolytic silver-strike, for components with complex geometries, as telecom filter cavities, in order to reduce

edge effects, improve tolerances and improve electrical performance.

Plating of ASIG, (Autocatalytic Silver Immersion Gold), as final finish for PCB's:

Excellent RF properties for high frequency PCB's.

Nickel free, eliminates black pads and brittle intermetallics.

Excellent for soldering and aluminium and gold wire bonding.

Space applications of ASIG for PCB's and autocatalytic silver on microwave components have been evaluated for ESA (European Space Agency),

by the Swedish research institute RISE IVF. ASIG finish provided good solderability even after having been exposed to two soldering processes,

and autocatalytic silver-plated microwave components meet both RF- and space environment requirements.

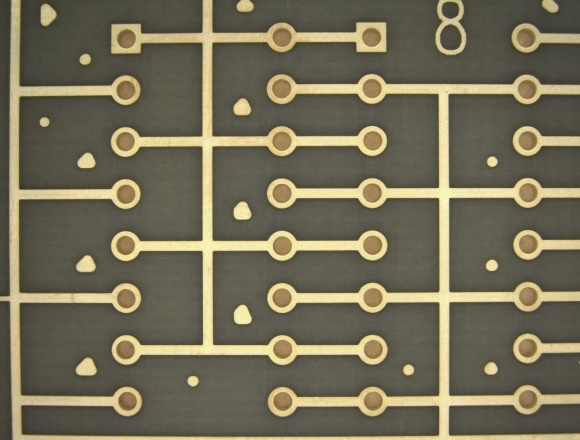

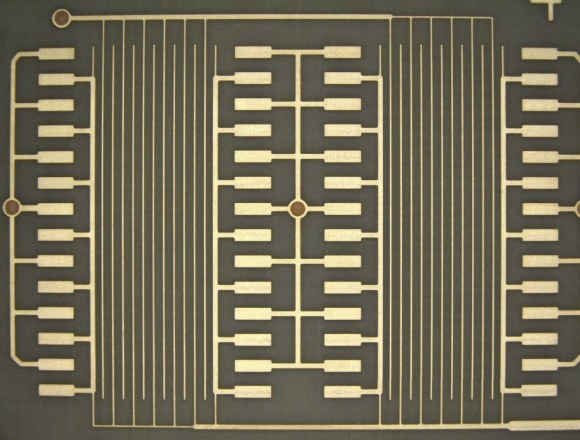

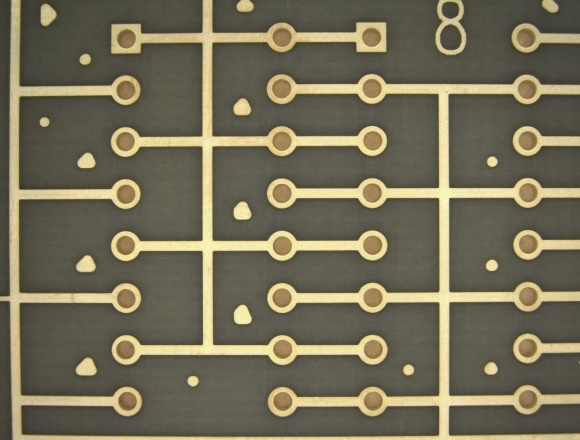

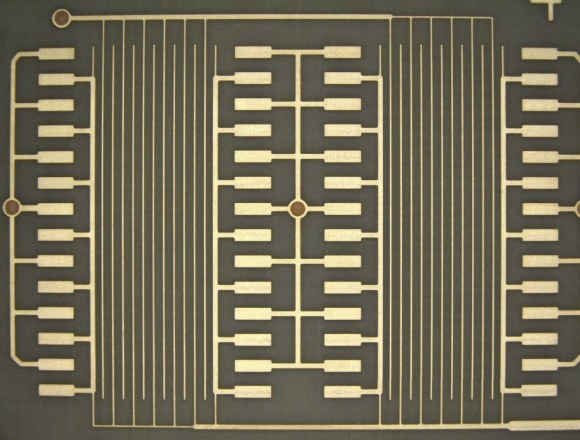

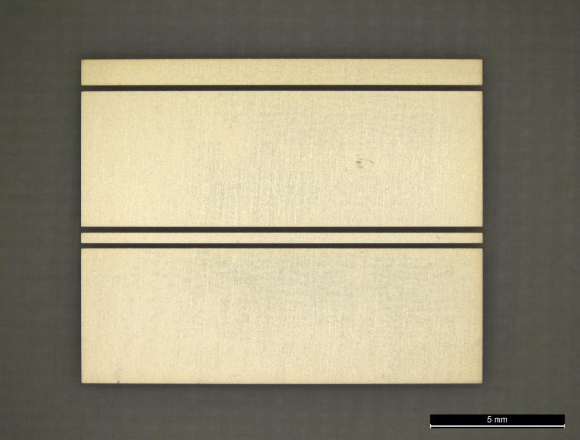

ASIG plated PCB

ASIG plated PCB

ASIG plated PCB

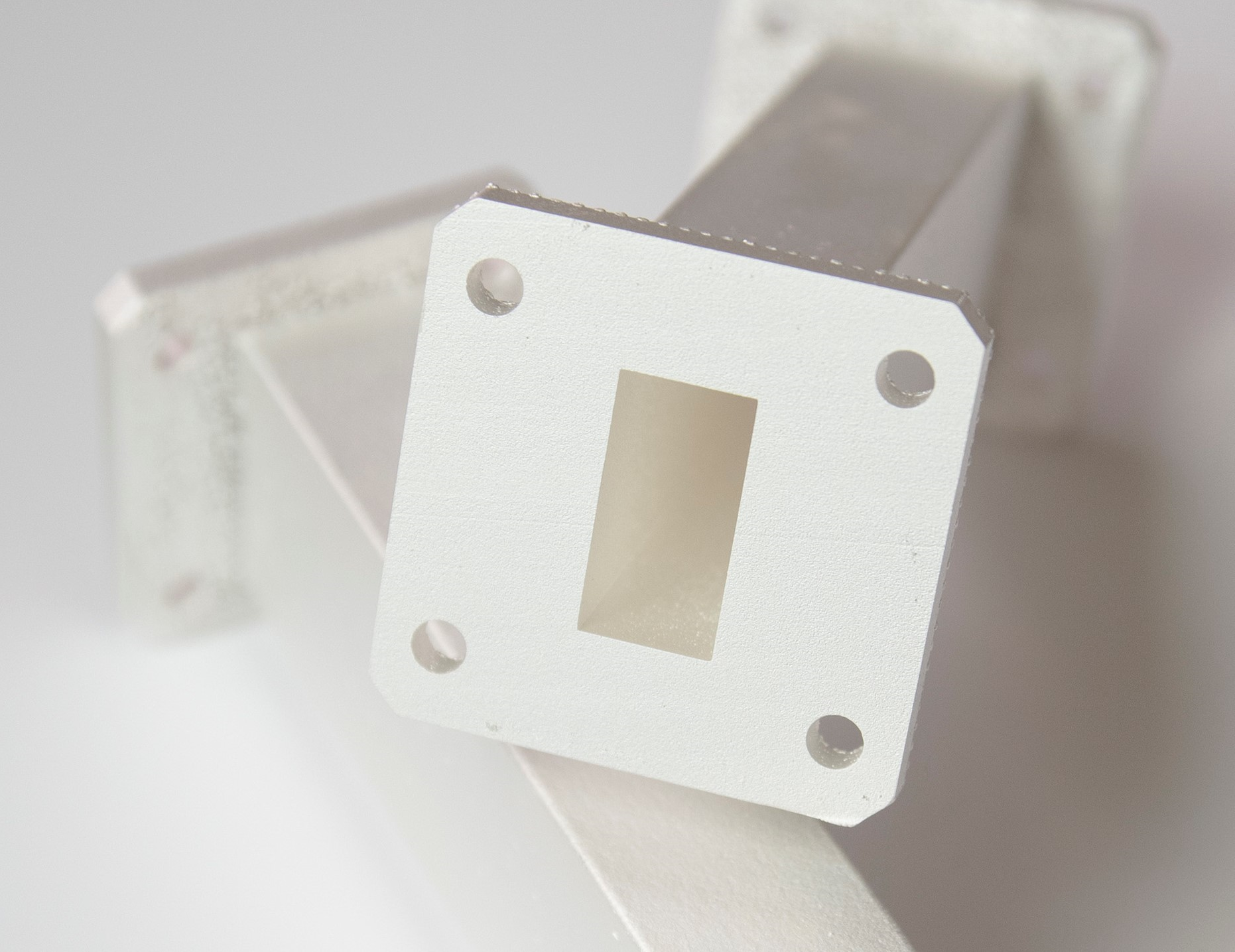

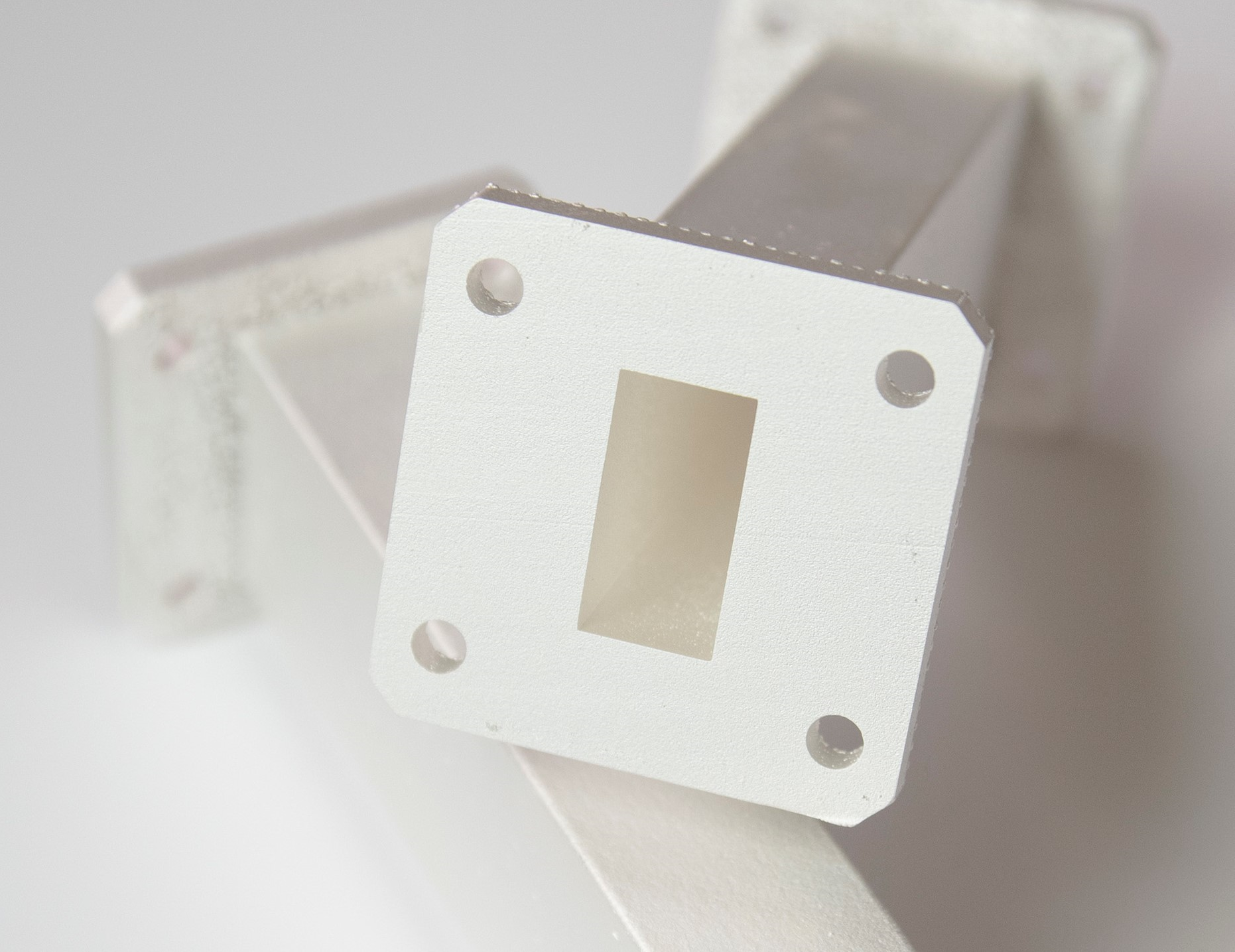

5 micron autocatalytic silver plated 3D-printed aluminium waveguide

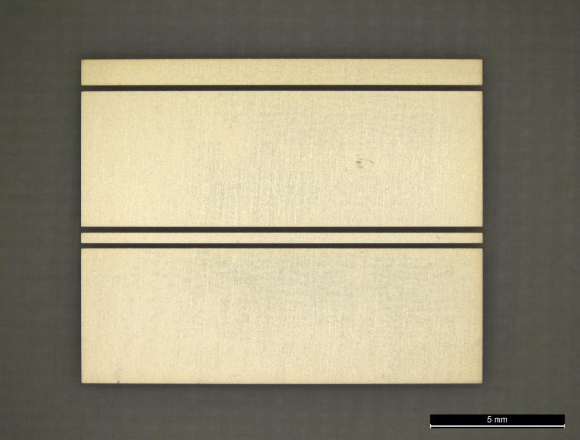

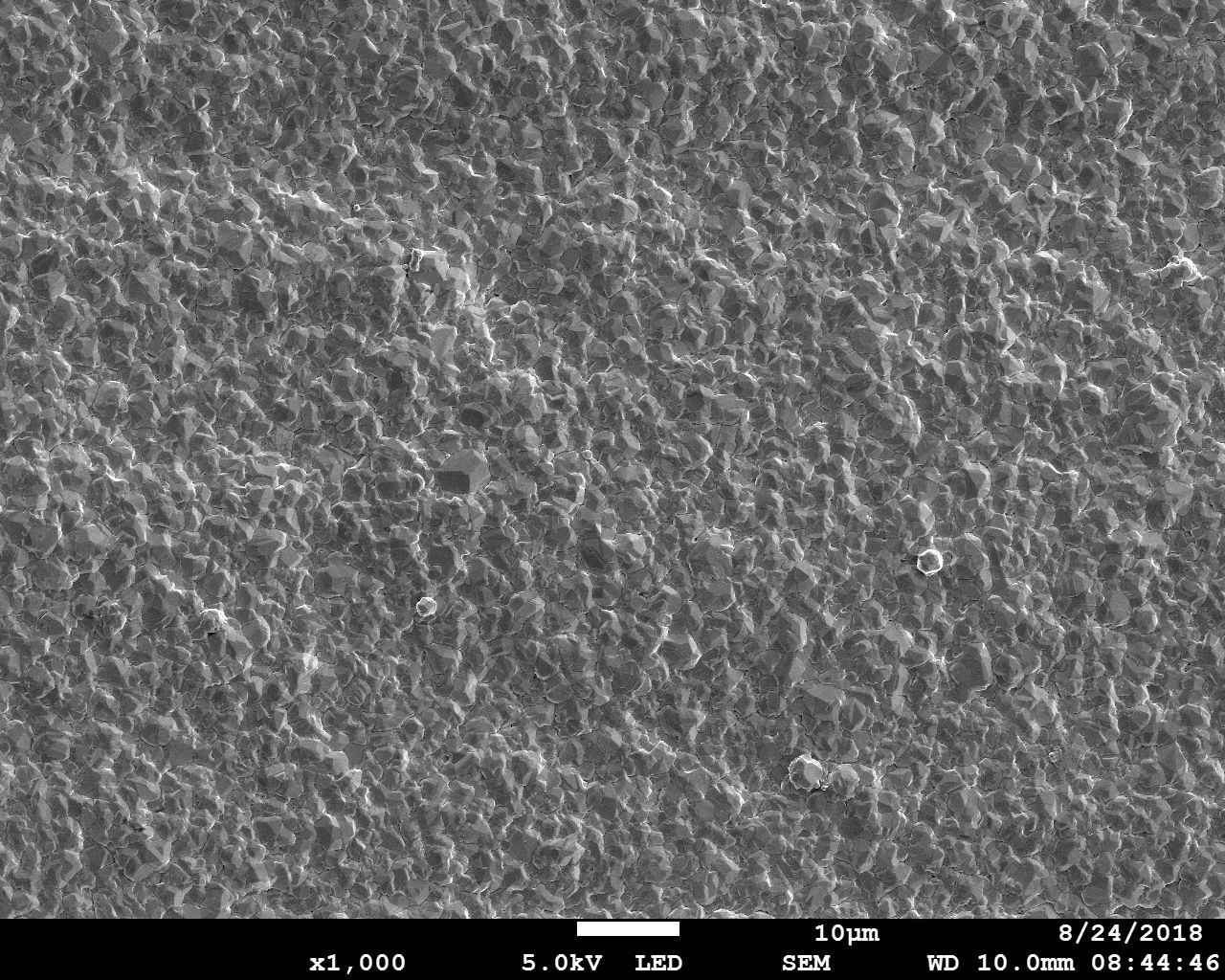

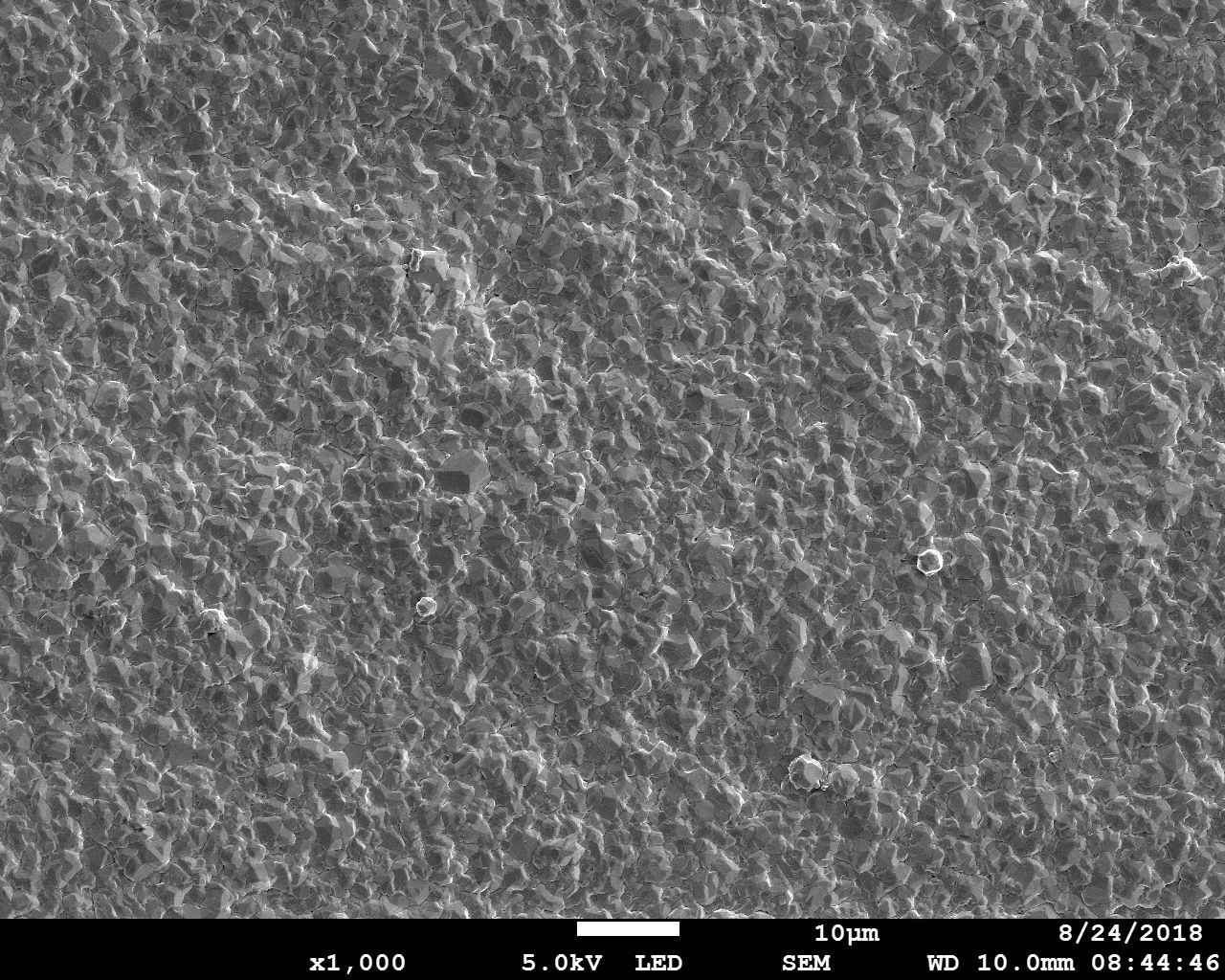

Autocatalytic silver microstructure: 1000 times magnification

5 micron autocatalytic silver-plated, dip brazed aluminium waveguide

Business offer

We offer License Agreements for the processes: ESM 100 / ESM 200 / NIAG-Activator / Ag-Barrier.

We will make a quotation for supply of documentation and key-additives for initial trials.

This will enable for the customer, to set up the processes in house and perform evaluation.

After test completion and if contented, license agreement can be arranged.

Please contact us and describe your interest/application and we will send technical data sheets

regarding the processes mentioned above, by e-mail.

We are happy to collaborate with you!

About us

Our technology for autocatalytic silver has been developed by Anders Remgård, founder and CEO of

Autocatsilver AB. Anders has a MSc in Chemical Engineering and has been active as an

inovator and entrepreneur within the field of silver-plating since early 90s.

Emma and

Marcus are members of our Advisory Board and have both experience in process development, testing

and documentation of our processes.

Anders, CEO, MSc Chemical Enginnering

Emma, MSc Mechanical Engineering

Marcus, MSc Engineering Physics